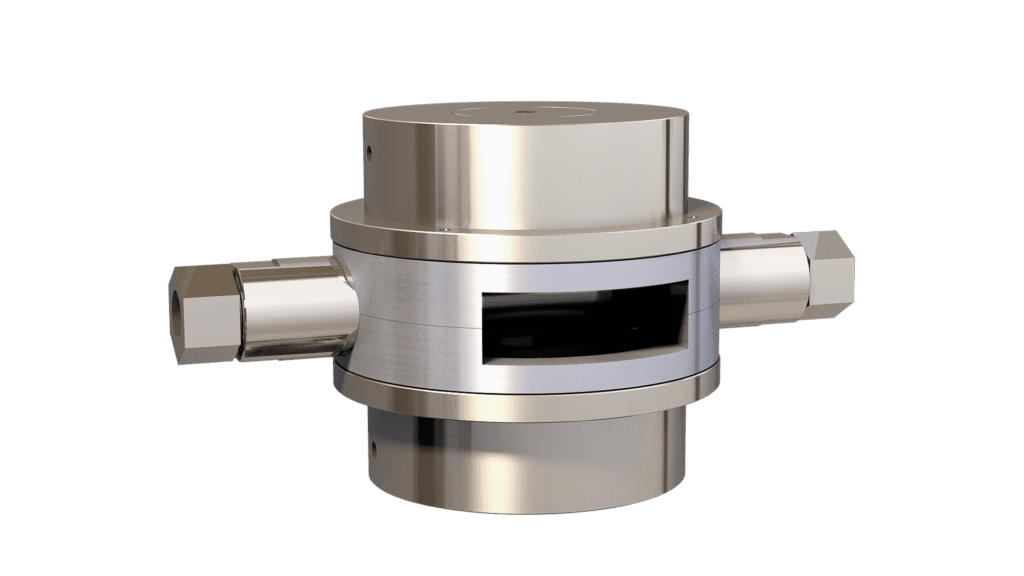

MicroSilicon’s real-time IoT sensors for the Oil & Gas Industry provide a unique platform technology to address flow assurance problems from reservoir to refinery and solve the “cholesterol” problems of oil production. The Quantum RF Analyzer is the world’s first in-field, harsh environment, real-time Asphaltene analyzer for permanent online monitoring and provides automated asphaltene measurements at line pressure and temperature. It is connected to the Cloud for data processing and with analytics to provide key insights into production systems including fluid typing and prediction of asphaltene deposition.

Specifications

Dimensions: 24 x 27 x 55 inch

Weight: 400 lbs.

Electrical: 24 VDC, 50/240 watts (cont./ peak)

Communications: Ethernet/Wi-Fi/Cellular

Pressure rating: 2,250 psi

Temperature rating: 125 C

Classification: Class 1 Division 2 GRP D T4

Measurements

Asphaltene: 0.05% resolution

Temperature range: 0-65 C

Pressure range: 0-2250 psi

Advanced Micro Sensors

for industrial process monitoring

Attain unprecedented levels of operational efficiency, productivity, and competitive advantage.

Online Integration

Solutions that integrate our sensor to your existing infrastructure.

Real-Time Analytics

Data when you want it. Dynamic analysis and reporting to understand your well, on the spot.

Data Insights

Understand your data and get full insights from a comprehensive set of machine learning algorithms.

Hostile Environments

High Pressure & High Temperature technology in tight spaces.

IoT Technology

Seamless integration of our sensor to the internet for full control of devices.

Alerts

From email reports to real-time phone calls. Customize your alerts and be better prepared for eventualities.

QuantumRF

Discover the full power of online chemical sensing

Our first product is an Asphaltene & Corrosion Analyzer that can monitor and analyze the chemical contents of hydrocarbon fluids in real-time.

Oil & gas operators spend billions each year mitigating asphaltene buildup

Sensor installed in flowlines from reservoir to refinery

Stop Inaccurate Dosing

Target right chemical, in the right amount, at the right time.

Respond Dynamically

Change operational conditions. Don’t wait for days to learn impact of changes.

Plan Ahead

Detect problems before they occur and update maintenance schedule as needed.

Reduce Costly Repairs

After the fact repairs are much more expensive. Be prepared before they happen.

Increase Production

Reduce the frequency and length of outages.

Extend Life of Assets

Extend time between repairs by operating equipment optimally.